Tokyo (SCCIJ) – Researchers at the Zurich University for Applied Sciences (ZHAW) have succeeded for the first time in propagating cocoa cell cultures in a bioreactor and producing chocolate with an intense aroma from them. The first chocolate bar should come to stores in 2023.

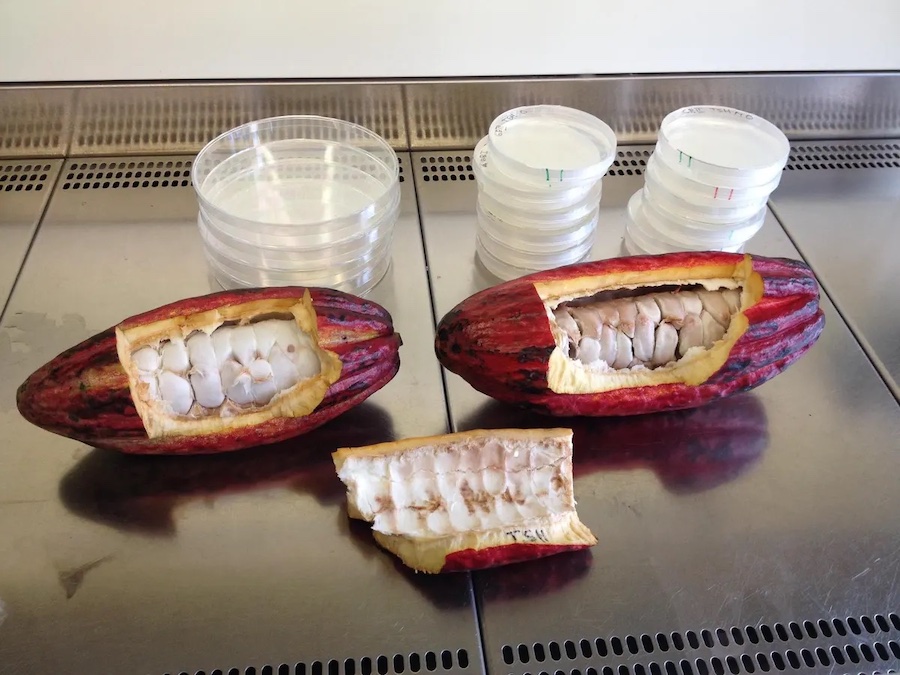

At the laboratory, the cacao fruit is cut open and the beans are taken out (© ZHAW).

Nature as source

The chocolate value chain may be divided into two areas. Currently, the cocoa fruits are harvested in the respective country of cultivation and the cocoa seeds obtained from them are fermented locally. Then the cacao beans are processed and refined into chocolate in the consumption countries. In contrast, cell culture technology understands nature as a unique source instead of a consumable resource.

The method called cellular agriculture imitates processes from nature in the laboratory. Cocoa growers will still make a living. But lab chocolate may avoid problems associated with the conventional production, such as overuse of the soil and exploitative working conditions. The reason: Any number of new panels can be made from the cell cultures after they are obtained.

Technologically, there are no major hurdles to producing cocoa without a tree, even on a large scale. The pharmaceutical sector has been using the technology of cell propagation in bioreactors already for a long time to produce vaccines and ingredients for cosmetic products.

The aroma of chocolate can be broken down into 25 substances (© ZHAW).

Cell growth

The Swiss researchers at ZHAW obtained freshly harvested but still immature Theobroma cacao fruits from the “Tropical Agriculture Research Station” in Puerto Rico. The cell cultures were first induced as callus cultures from the cacao seeds and subcultured every two to four weeks on a new medium. This allows for unrestricted further cell growth as well as cell division.

After 16 days in a wave-mixed 20-liter single-use bioreactor, approximately 300 grams of cocoa biomass was harvested, separated from the culture broth, rinsed, and freeze-dried. The cocoa cell material was subsequently incubated. This is considered an alternative to microbial fermentation of cocoa beans, which is necessary for the development of typical chocolate flavors.

Intense aroma

The result of this work in the laboratory is an aroma-intensive cocoa powder, which can be used to produce chocolate by adding the usual ingredients such as milk and sugar. To make affordable chocolate, this process has to be streamlined on a bigger scale.

An initial sensory evaluation of the model chocolate produced from the ZHAW cocoa powder revealed an intense and complex aroma with a predominance of citrus and berry flavors. In addition, lactic, malty, greenish, and vegetal notes as well as a slightly sour component were attributed to the sensory profile.

Additionally, ZHAW researchers have broken down the aroma substances in cocoa and chocolate and developed an aroma kit with 25 reference substances. The Aromakit Cocoa can be used as a training tool for sensory panels as well as for interested chocolate connoisseurs and is available for orders at the ZHAW (Link).

Text: Martin Fritz for SCCIJ based on ZHAW reports