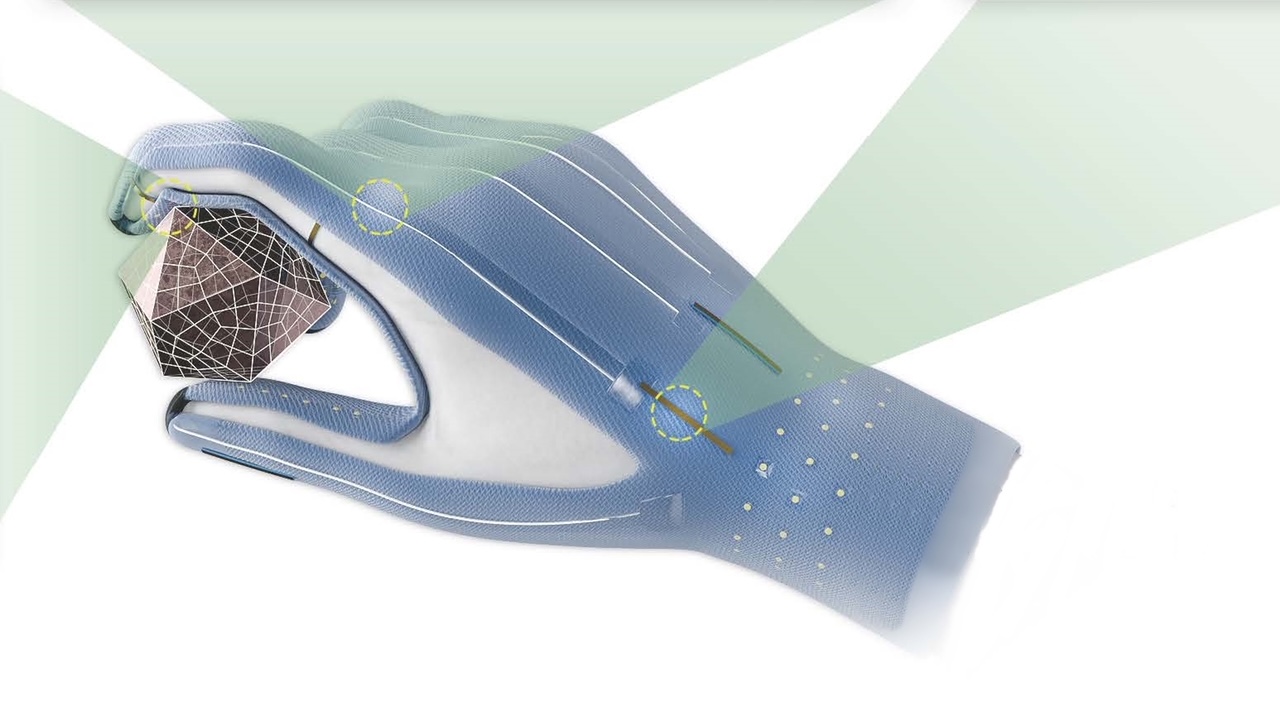

Tokyo (SCCIJ) – Swiss researchers are working on a virtual reality glove equipped with artificial muscles. It is to be tailored to each user and to be produced largely automatically – using a 3D printing process.

The Swiss VR glove will have artificial muscles (© Herbert Shea/EPFL).

Printing challenge

With their research on electroactive polymers, Dorina Opris and Patrick Danner are part of a large-scale project called “Manufhaptics”. The goal of the four-year project, led by Herbert Shea of the Soft Transducers Lab at the Swiss Federal Institute of Technology in Lausanne (EPFL), is a glove that makes virtual worlds tangible.

Crucially, all of the glove’s components, which exert various forces on the surface of the hand, are to be producible in a 3D printer. Consequently, this is about research into new materials, with the production method being considered from the very start.

Three types of actuators

To make virtual surfaces feel real and objects tangible at the right size, the research teams from EPFL, the Swiss Federal Institute of Technology in Zurich (ETHZ), and the Swiss Federal Laboratories of Material Sciences (Empa) want to integrate three different types of actuators into the glove.

Underneath the fingers, nubs can grow up to replicate a specific texture of a surface. In the area of the finger joints, electrostatic brakes are mounted that stiffen the glove and block the joints. This simulates larger, solid objects that offer resistance when touched.

The third type of actuator that completes the virtual experience is called DEA (Dielectric Elastomer Actuator). These DEAs are used on the back of the hand; they tighten the outer skin of the glove so that it fits perfectly at all points. During the VR experience, they can also apply pressure to the surface of the hand. Empa researchers are in charge of the DEAs.

Artificial muscles can be produced automatically in a 3D printer (© Empa)

“Printed Muscles”

Dorina Opris, the head of the research group, says about electroactive polymers: “They react to electric fields and contract like a muscle,” she explains. “But they can also serve as a sensor, absorbing an external force and generating an electrical pulse from it. We’re also thinking of using them to harvest energy locally: Their movement can generate electricity.”

The Manufhaptics project presents new challenges for Opris and her colleague Patrick Danner. “Until now, we have produced our polymers using solvents through a chemical synthesis,” explains Opris. Now everything has to work without solvents: The plan is to superimpose up to 1000 fine layers from the 3D printer, always alternating between the electroactive polymer and a current-conducting layer.

After a long series of tests, Patrick Danner found a promising formulation – a cream that is liquid enough and at the same time dimensionally stable, and from which electroactive polymers can be created in a single step.

His colleague Tazio Pleij at ETH Zurich has successfully processed the material in his 3D printer into several layers – always alternating between polymer and electrode material. There are not yet 1,000 layers, but only about 10, and the artificial muscle from the 3D printer does not yet function satisfactorily. Thus, Opris and Danner are confident of mastering the task together with the printing specialists at ETH Zurich – possibly as the first team in the world.

Text: SCCIJ based on material of EDA