Tokyo (SCCIJ) – A team of researchers of the Swiss Federal Laboratories for Materials Science and Technology (Empa) in Dübendorf near Zurich have invented a new concrete formula. Hence, they can build lean structures more cost-effectively and save material at the same time. As a result, concrete becomes a much more climate-friendly construction material.

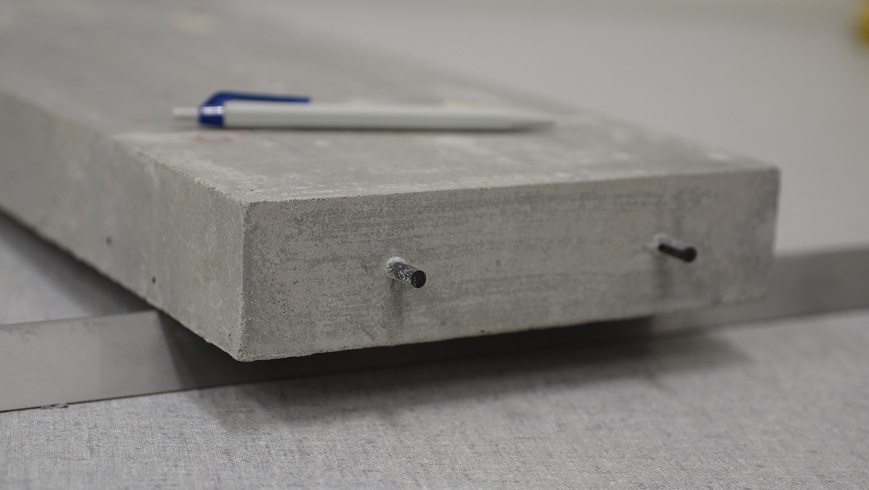

A beam made of self-pre-stressed concrete with carbon fiber reinforced plastic (CFRP) as reinforcement (© Empa).

High emissions

Cement, the binding agent in concrete, is the main culprit, as it is responsible for up to eight percent of the global CO2 emissions mainly through the use of fossil fuels. According to estimates, the annual production of concrete and cement could even increase by another 50 percent by 2050 due to growing demand in developing countries.

Replacing concrete is not an easy task, though; the building material offers too many advantages. But an improved concrete – from production and efficient use of materials to demolition and recycling – would have an enormous impact on our environment and society. Thus, Empa scientists are looking into developing methods to make concrete elements leaner, yet durable and stable, which reduces materials consumption.

Carbon fibers instead of steel

A team led by Giovanni Terrasi, Pietro Lura, and Mateusz Wyrzykowski recently received a European and a US patent for a self-pre-stressing concrete technology that achieve just this.

Conventionally, reinforcements of steel are used to produce concrete elements that can withstand very high loads needed in beams and bridges.

The problem: Steel is susceptible to corrosion. Hence, the concrete layer around the pre-stressing steel must have a certain thickness. A well-known alternative solution is carbon fiber-reinforced polymers (CFRP). This material does not corrode and allows significantly leaner components.

But the complex and expensive process to produce such CFRP enforced concrete has impeded its widespread use. Now, the Empa team has been able to dramatically lower production costs by simplifying this process. The researchers removed the need for expensive pre-stressing beds and complicated anchoring procedures that were needed until now.

New applications enabled

Thanks to a special formula, the concrete expands as it hardens. As a result, the concrete puts the CFRP bars in its interior under tension and thus automatically pre-stresses itself. “Our technology opens up completely new possibilities in lightweight construction,” says Empa researcher Mateusz Wyrzykowski. “Not only can we build more stable structures, but we also use considerably less material.”

The Empa researcher also envisions completely new fields of application: “We can easily pre-stress in several directions at the same time, for example for thin concrete slabs or filigree curved concrete shells,” he says, looking to the future. These new applications are now being developed further in cooperation with an industry partner.

Text: Material of Empa edited by SCCIJ