Tokyo (SCCIJ) – Researchers from the Swiss Federal Institute of Technology (ETH) Zurich have developed an arm for miniature robots. Until now, microscopic robotic systems have had to make do without such a tool.

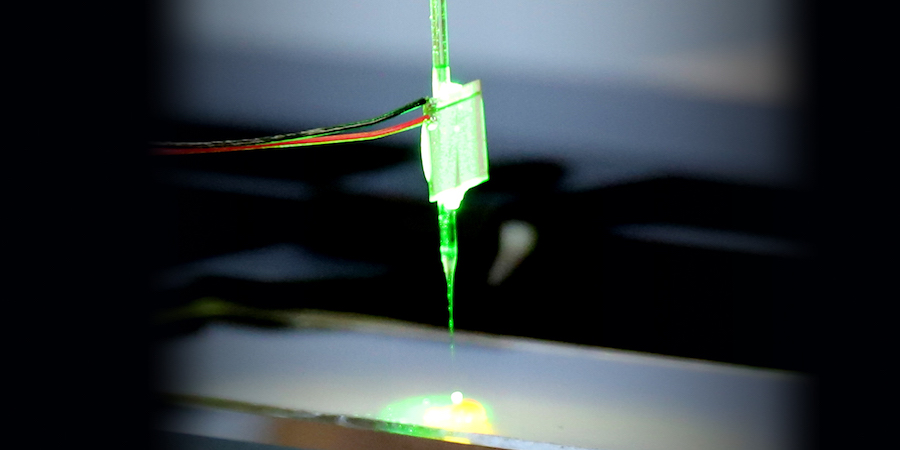

Caption: Using a glass needle made to oscillate with the assistance of ultrasound, liquids can be manipulated and particles can be trapped (© ETH Zurich).

Lab-on-a-chip robot

Robots equipped with moving arms stand in factory halls, perform mechanical work, and can be programmed. A single robot can be used to carry out a variety of tasks. Until today, miniature systems that transport minuscule amounts of liquid through fine capillaries have had little association with such robots.

Developed by researchers as an aid for laboratory analysis, such systems are known as microfluidics or lab-on-a-chip and generally make use of external pumps to move the liquid through the chips. Such systems have been difficult to automate, and the chips have had to be custom-designed and manufactured for each specific application.

Pointed glass needle

Now, scientists led by ETHZ Professor Daniel Ahmed are combining conventional robotics and microfluidics. They have developed a device that uses ultrasound and can be attached to a robotic arm. It is suitable for performing a wide range of tasks in micro-robotic and microfluidic applications and can also be used to automate such applications.

The device comprises a thin, pointed glass needle and a piezoelectric transducer that causes the needle to oscillate. Similar transducers are used in loudspeakers, ultrasound imaging, and professional dental cleaning equipment. The ETH researchers can vary the oscillation frequency of their glass needles. By dipping it into a liquid they create a three-dimensional pattern composed of multiple vortices. Since this pattern depends on the oscillation frequency, it can be controlled accordingly.

Proved applications

The researchers demonstrated several applications. They were able to mix tiny droplets of highly viscous liquids and pump fluids through a mini-channel system by creating a specific pattern of vortices and placing the oscillating glass needle close to the channel wall. Also, they used their robot-assisted acoustic device to trap fine particles present in the fluid.

“Until now, advancements in large, conventional robotics and microfluidic applications have been made separately,” Ahmed says. “Our work helps to bring the two approaches together.” As a result, future microfluidic systems could be designed similarly to today’s robotic systems.

Future devices

An appropriately programmed single device would be able to handle a variety of tasks. “Mixing and pumping liquids and trapping particles – we can do it all with one device,” Ahmed says. This means tomorrow’s microfluidic chips will no longer have to be custom-developed for each specific application.

In addition to laboratory analysis, Ahmed can envisage other applications for micro-robotic arms, such as sorting tiny objects. Also, such arms could conceivably be used in biotechnology to introduce DNA into individual cells. It should ultimately be possible to employ them in additive manufacturing and 3D printing.

Text: ETHZ (editing by SCCIJ)