Tokyo (SCCIJ) – The Swiss Federal Institute of Technology in Lausanne (EPFL) and the Swiss Center for Electronics and Microtechnology (CSEM) have joined forces to create the Micromanufacturing Science & Engineering Center. This new focal point for technology research aims to support the Swiss manufacturing industry.

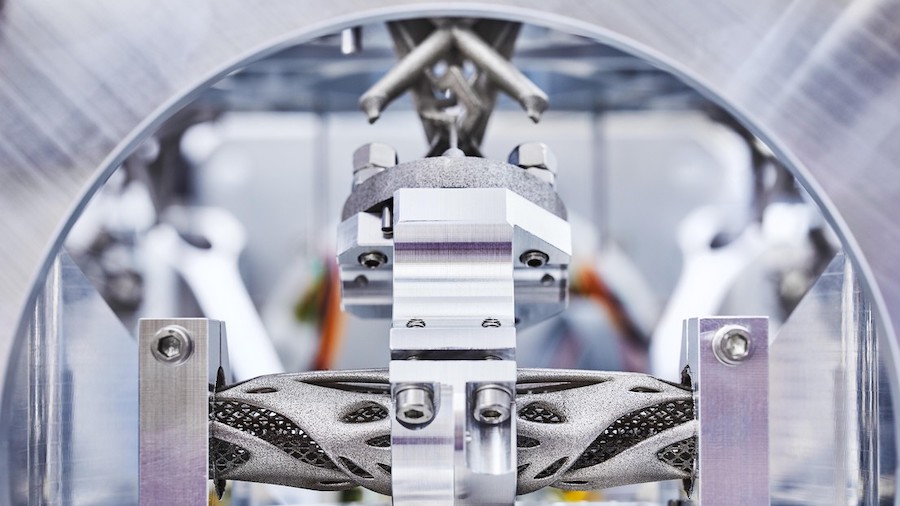

Advanced additive micro-manufacturing allows the production of very complex parts (© CSEM).

Development support

The Micromanufacturing Science & Engineering Centre, shortened to M2C, focuses on high-precision 3D microfabrication. It will cover every step of the development process, from basic research in EPFL laboratories to the transfer of sustainable, high-value-added technologies to industry under the leadership of CSEM. The new center will act as a catalyst for collaboration between academic, institutional, and industrial partners, as well as an education and training platform for members and users.

“3D manufacturing methods are raising the bar in terms of precision and digitization,” says Bruno Studach, operational director of advanced manufacturing at EPFL. “These disruptive techniques are changing the industrial landscape, leading us to a future where objects and computers are increasingly connected. Investing in these rapidly evolving fields is essential if we want to stay ahead of global competition and at the forefront of innovation. The M2C was created with these challenges in mind.”

Additive manufacturing, also known as 3D printing, builds objects from successive layers of material. Its growing popularity can be attributed to the fact that it unleashes creative freedom and allows engineers to build complex, yet lightweight and robust components. 3D printing can digitize every step of the process, from design to production. What is more, a single machine can produce radically different objects. Scientists and engineers at M2C will explore ways to capitalize on new materials and production systems through design, development, and testing.

Broad appeal

Because of their unique properties, 3D-printed parts appeal to sectors and industries as diverse as space exploration, custom prosthetics, microfluidic devices, and watchmaking. In addition, because sensors and other technologies can be incorporated directly into these parts, they open the door to the collection of diverse and accurate data sets for applications such as predictive maintenance and complex system monitoring.

The M2C team will develop solutions for systems and components on scales from a few microns to tens of centimeters. The center’s work is in line with the Swiss Technology Institutes’ strategic focus on advanced manufacturing. “This multidisciplinary alliance will allow EPFL and CSEM laboratories to share state-of-the-art facilities and work together to accelerate the introduction of new manufacturing technologies,” says Olha Sereda, group leader for additive manufacturing at CSEM. “This means that Swiss manufacturers will continue to push the boundaries of innovation and remain competitive on the global stage.”

Text: Laure-Anne Pessina/CSEM via EPFL News