Tokyo (SCCIJ) – ABB from Switzerland and Kawasaki Heavy Industries from Japan, both global leading players in industrial automation and robotics, have developed the world’s first common collaborative robot operating interface. Such cobots or co-robots are intended to physically interact with humans in a shared workspace. With a common operating interface, any user could use a cobot and integrate it into a production process. This will help address the shortage of skilled workers in many industries. In Japan for example, one person in five is within a decade of retirement.

Next step in automatization

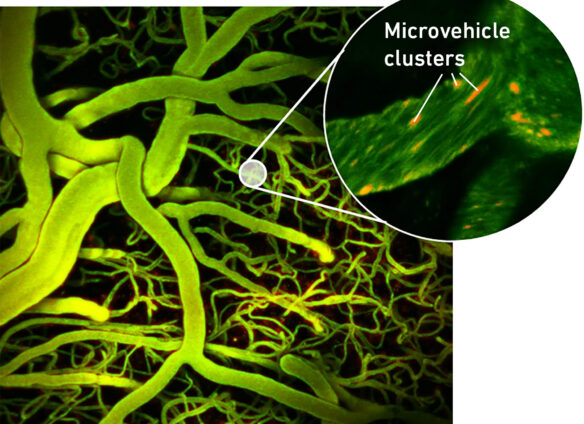

ABB and Kawasaki Heavy Industries are showcasing their operating interface for the first time ever at the trade fair automatica in Munich, Germany (June 19-22). A joint collaborative automation demonstration located at the East Entrance of automatica will feature Kawasaki’s unique and innovative Dual-Arm SCARA Robot “duAro” working together with ABB’s dual-arm YuMi robot. The interface is a result of the collaboration between ABB and Kawasaki announced in November of 2017 (SCCIJ reported earlier), designed to share knowledge and promote the benefits of collaborative automation, in particular dual-arm collaborative robots. It includes a simplified human–robot interface with intuitive, smartphone-like navigation and icons.

ABB/KHI cobots at automatica

Cobot advantages

Demand for collaborative robots has outpaced the rapidly-growing industrial robot market, as easier-to-use robots open doors to new users. The fact that collaborative robots can be programmed and operated by people without specialized training helps small and medium enterprises, in particular, to leapfrog traditionally longer industrial robot learning curves.

Collaborative robots (cobots) that can be operated by nearly any user can help offset labor shortages. Their flexibility to work nearly anywhere in a factory without safety barriers also makes them ideal for meeting sudden and unexpected demand peaks.

Rapid cobot growth

“The new state-of-the-art, industry-standard operating interface will accelerate the already rapid growth we see in collaborative robots,” said Per Vegard Nerseth, Managing Director of Robotics for ABB. “It will give many new manufacturers flexibility and scalability, while providing more interesting jobs for the world’s vital industrial workforce.”

Yasuhiko Hashimoto, Managing Executive Officer and President of the Precision Machinery and Robot Company, Kawasaki Heavy Industries, said: “It is entirely appropriate that we usher in a new age of collaboration automation with a collaborative approach. Collaborative robots will make a large contribution to society in making manufacturing more flexible and efficient and in keeping our factories productive with an increasingly scarcer workforce.”

In addition to continued development of the operating interface, the collaboration also focuses on other topics such as common safety standards. Traditional industrial safety standards are based on years of practice, supported by very specific parameters. The goal for collaborative automation is to develop safety standards which ensure worker safety, but also allow for entirely new ways of working together without unduly restricting collaborative robots’ many benefits.

About ABB

ABB is a pioneering technology leader in electrification products, robotics and motion, industrial automation and power grids, serving customers in utilities, industry and transport & infrastructure globally. Continuing a history of innovation spanning more than 130 years, ABB today is writing the future of industrial digitalization with two clear value propositions: bringing electricity from any power plant to any plug and automating industries from natural resources to finished products.

ABB Robotics is a pioneer in industrial and collaborative robots and advanced digital services. As one of the world’s leading robotics suppliers, it is active in 53 countries and over 100 locations and has shipped over 400,000 robot solutions in a diverse range of industries and applications. It helps its customers to improve flexibility, efficiency, safety and reliability, while moving towards the connected and collaborative factory of the future.

About Kawasaki Heavy Industries

Kawasaki is now recognized as a global leader in diverse industries in wide ranging fields going beyond land, sea and air, offering state-of-the-art technologies for environmental and energy infrastructure, machinery and robotics, and various types of transportation in marine, railway and aerospace to leisure vehicles as motorcycles and personal watercraft in global basis with about 35,800 employees.

Kawasaki Robotics is a leading supplier of industrial robots and robot automation systems with a broad product portfolio, having shipped 180,000 robots in about 50 countries. As a pioneer in Japan, Kawasaki celebrates its 50th anniversary in 2017. As one of the world’s leading robotics suppliers, it is now transforming itself from an industrial to a fully integrated robot supplier. Kawasaki is a solution provider having deep application know-how through diverse business and products on land, sea and air.

Text: SCCIJ with material of ABB; Photo: ABB