Tokyo (SCCIJ) – Swiss International Air Lines (SWISS) is taking a pioneering role in reducing the carbon dioxide emissions of the aviation industry. It will be the first airline to use “sun-to-liquid” kerosene to power planes. Additionally, a new skin technology will improve the aerodynamics of its aircraft. SWISS intends to make passenger flights more sustainable and climate-friendly.

SWISS has set a goal to fly carbon-neutral by 2050 (© SWISS).

Solar kerosene

SWISS and the Lufthansa Group have concluded a strategic collaboration with the Synhelion company to bring its solar aviation fuel to market. The unique process of Synhelion uses concentrated solar heat to manufacture syngas. Standard industrial processes synthesize this gas into kerosene.

This sun-to-liquid fuel closes the fuel carbon cycle: when combusted, it will only produce as much carbon dioxide as went into its manufacture. The new fuel thus makes a major contribution to effectively decarbonizing air transport.

Synhelion will build the world’s first-ever facility for the industrial production of solar fuel in Jülich (Germany) this year. SWISS is set to become the first customer for this solar kerosene in 2023. Under the collaboration now concluded, SWISS and the Lufthansa Group will also support the development of Synhelion’s planned commercial fuel production facility in Spain.

“Reducing the environmental footprint is one of the greatest challenges ahead for the aviation sector, and being carbon-neutral in our flying by 2050 is a key SWISS strategic objective,” says CEO Dieter Vranckx. “We put a major emphasis on actively promoting and making targeted investments in new technologies.”

Aerodynamic surface

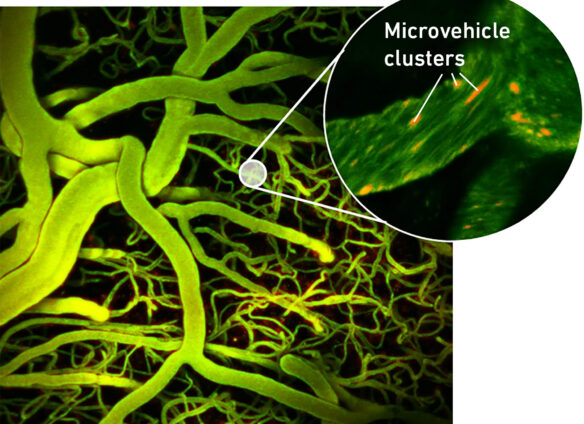

SWISS is also the first passenger airline to take advantage of a new aircraft skin technology to reduce significantly the aerodynamic drag of a flying aircraft. The “AeroSHARK” riblet film will be applied to the fuselage and engine nacelles. As a result, fuel consumption decreases, and with it the carbon dioxide emissions.

Lufthansa Technik and chemicals manufacturer BASF developed the technology. The film features millions of ‘riblets’ – small protrusions just 50 micrometers high – which replicate the highly hydrodynamic skin of sharks.

SWISS will put the film on all twelve Boeing 777-300ER aircraft starting from mid-2022. Already collected data will be used for high-precision 3D airflow simulation models to develop a riblet film also for the wings, to tap further fuel and emission savings potential.

By applying a total of 950 square meters of this riblet film to the fuselage and engine nacelle surfaces of a Boeing 777, SWISS achieves fuel savings of some 1.1 percent. The annual fuel consumption of its Boeing 777 fleet goes down by 4,800 tons, and the total annual carbon dioxide emissions by as much as 15,200 tons – the same amount that 87 long-haul flights from Zurich to Mumbai would emit.

Text: SCCIJ based on material of SWISS